One of our specialities: Custom-tailored in large sizes.

Standard products are not of much use when nothing is defined by standards, when everything has to be custom-made and individually adapted. Industrial fire engine are so unique, they have to be configured to exactly meet the customer’s needs, which are typically highly specialised. Two or three-axle chassis variants with strong engines, different cab sizes, all types and quantities of extinguishing agents, special proportioning systems, high-performance pumps, monitors, telescopic extinguishing booms, lighting systems, winches, special load configurations: Vehicles that combine all that to form a 100% deployment-ready unit can’t be just thrown together. They require an enormous amount of engineering expertise, long years of experience and a horizon that goes well beyond the workbench – put simply: Professionalism That’s also a standard. And it’s our standard.

Unique detailed solutions for special fire engines for the industry, refinery and chemicals sectors.

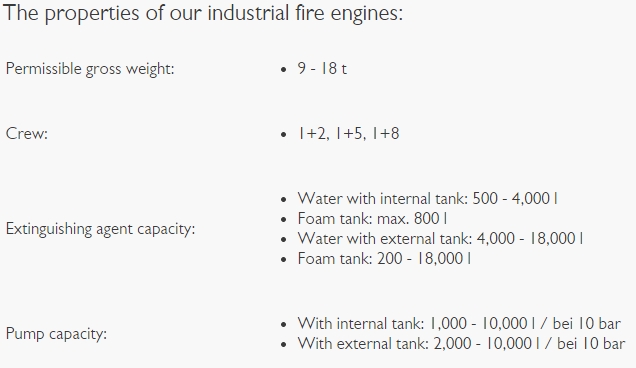

You specify the requirements, we’ll build the vehicle. Special fire-fighting chassis variants are available in any desired tonnage. We can realize the ideal solution for you with a wide range of cab variants and highly flexible superstructure concepts.

Superstructure concept: Internal tank

If the focus is on equipment and the crew, then a superstructure concept with an internal modular tank is ideal. It offers plenty of storage space and maximum flexibility for loading according to tactical necessity and individual requirements.

High-volume superstructures

This concept offers plenty of storage space alongside the tanks. Lowered equipment lockers (some optional) between and behind the axles add even more available space.

Modular tank system

The modular system is flexible – both in terms of water and foam volume and in the position of the tanks in the vehicle. Three different tank widths are available. Narrow tanks allow deeper equipment lockers. Tailor-made extinguishing medium solutions are available due to different tank widths and modular foam tank combinations.

Superstructure concept: External Tank

The principle “High-Performance Extinguishing Specialist”

The superstructure concept with an external tank is ideal when large amounts of different extinguishing media are needed. The additional equipment is used primarily for fighting fires. Special extinguishing systems such as powder, CO2, gels etc. are also available, depending on your requirements.

Large tanks transverse to the rear axle(s) enable the implementation of up to 18,000 l of extinguishing agent. Individual solutions with special extinguishing systems such as foam, powder or CO2 are also available, e.g. for industrial plant fire brigades.

High-capacity monitors

High-capacity monitors with a spraying performance of from 400 to 6,000 l/min ensure precisely targeted extinguishing power. They can be mounted on the driver’s cab, the superstructure roof or the bumper and can be operated manually or remotely via radio or cable connection.

A variety of foam pipes are available, including self-priming pipes as well as combined monitors with multiple pipes for using water, foam and powder.

AluFire 3

Rely on the original: AluFire 3

Magirus invented the aluminium superstructure for fire-fighting vehicles. In its third generation, the AluFire system has already proven thousands of times that it is more flexible, intelligent, powerful and successful than ever.

Robust. Lightweight. Uncomplicated.

Specially designed for Magirus, the anodised aluminium profiles are highly resistant, stable and extremely long-lasting. Fewer overall components mean reduced weight and simplified maintenance and repairs. We guarantee against rust-through for 12 years – only in connection with a maintenance contract.

You get three dimensions of flexibility.

Surrounded 360° by aluminium carrier bands for full loading flexibility: This enables uninterrupted floor to roof loading. Panel-shelves can also be inserted without the need to remove any components.

Heavy-duty and long-lasting solution.

Highly stable sandwich floors are extremely strong. Countersunk screws prevent injuries and damage to equipment. Smooth-surfaced floors are easy to clean.

Permanently installed Magirus pumps

The tail-mounted Magirus pump is powered by a chassis motor via a drive shaft. The built-in fire pump is connected to the fire-fighting water tank and the rapid water release unit or (as an option) to the quick attack hose reel. The low pump control stand features ergonomic operation. The pump valve in suction intake A enables input pressure of up to 12 bar. That means that higher hydrant pressures or pumping water over long distances is no problem. Foam proportioning systems can be integrated on request.

Magirus Primatic self-priming system

Magirus Primatic is the heart of our pumps. It is particularly safe and low-wear. Its design is based on the membrane pump, which is known for its insensitivity to dirt. The self-priming system is switched on and off directly by pump pressure, without additional mechanical, hydraulic or electrical aid.

Magirus foam proportioning systems

Magirus offers two different foam proportioning technologies for creating Class A and B wetting agents and foam compounds as well as for alcohol resistant foam compounds, e.g. AFFF.

FireDos®

The almost completely maintenance-free FireDos® proportioning system ensures constant proportioning even with fluctuations in flow or operational pressure. Input pressure is generated hydraulically by the fire-fighting water flow.

FireDos® is available for operational pressures of up to 40 bar and covers wide flow and proportioning ranges; 40 to more than 10,000 l/min. The pressure foam proportioning system regulates all known liquid foam and fire-fighting agents with the widest possible range of viscosity and consistency.

Magirus CaddiSYS

Reliable. Flexible. Simple.

This user-friendly Magirus system with electronic foam generation makes intervention fast and efficient. The foam proportioning system has an electronically controlled pressure foam proportioning system in compliance with DIN 14430 as D2A8/0.1–6 and D2A16/0.1–6, with proportioning after the pump.

Further details:

Extinguishing foam mixture supplied to one quick attack unit and one or two B-outputs

Foam supplied from one or two foam tanks

Flow volume: Water from 80 up to a maximum of 2,000 l, foam up to a maximum of 30 l. Proportioning rates: 0.1 – 6%, 0.1 – 1% in 0.1%

Electric power from the 24 volt on-board power supply

Special features of Magirus CaddiSYS:

Electronically regulated three-cylinder piston pump, self-priming – constant proportioning of foam viscosity

Draw from external foam containers – flow meter for foam and water

Complete control of functions using the HMI control unit at the pump stand; simplest possible operation of most important functions via direct-access buttons

Comprehensive display of information such as fill levels, flow volumes, operation period remaining

Trouble-free mechanical emergency operations

Modular construction for simple installation and service

Additional features available

Magirus CaddiCAFS

The Magirus CaddiCAFS compressed air foam system is a highly efficient yet extremely easy-to-operate extinguishing system. It combines the benefits of the high-performance Magirus centrifugal pump, the exact regulation of the CaddiSYS pressure foam proportioning system and high-energy compressed air.

It can be configured for one-touch operation to automatically activate the following procedures:

Starting the vehicle engine

Engaging the P.T.O.

Bringing the pump to optimum output pressure

Activating the pressure foam proportioning system , which then mixes at the optimal proportioning rate

Compressor introduces compressed air into the water/foam compound flow

Compressed air foam is emitted

Using the system as a pure pressure foam-proportioning system (without compressed air) is just as easy as a switchover between wet and dry foam at the push of a button.

Your security:

Maximal reliability: In case of a compressed-air failure, the foam proportioning remains active; in case of a proportioning failure, the water stream is transported to the nozzle without obstruction: One-touch operation

Compressed air components are not activated until the foam compound is proportioned

Compressor and pump temperatures are monitored

System is not disturbed by wastewater

Optimum system cooling using water/oil heat exchanger; Made with reliable, inspected standard industrial components

Reliability through CAN-bus control

Protection against accidental selection of dry instead of wet foam

Magirus HMI cab control unit (Human Machine Interface)

Clear display of all functions, status values and possible warning messages with highly legible graphics and symbols

The display is easily viewed by the operator and vehicle driver for especially safe activation of functions

No retrofitted wiring or switches are necessary in the dashboard – for the greatest possible reliability

Simple integration and control of additional units via FireCan – the same operating logic used for the HMI pump control unit simplifies handling and training

The highest system security in the industry due to independent, double CAN control systems as well as pneumatic and manual emergency operation

Cab

Ready, Set – Go.

How efficiently and safely an operation runs isn’t decided when you arrive at the scene of action, but on your way there. This is why the practical layout of the driver’s cab and crew compartment is just as important to us as the way the equipment lockers are designed. We offer two different technologies for three applications.

All-steel technology

From a single mould: The special Magirus Fire-fighting chassis variants have crew compartments using all-steel technology integrated during vehicle assembly. As with mass-produced vehicles, cataphoretic full-immersion bath priming and several coats of paint guarantee optimum corrosion protection. The cab can be tilted hydraulically and is mounted on silent blocks. Thanks to generous side windows and an additional middle window, the crew members have an unusually good all-round view.

The generous height and width provide plenty of space for the crew. Three BA devices are available that face against the direction of travel; in addition, two BA devices can be installed facing the direction of travel. These are integrated in the rear wall of the cab so that no space is lost on the front superstructure wall and nothing interferes with the vehicle’s torsional flexibility.